Understanding the Ford 8N Ignition System

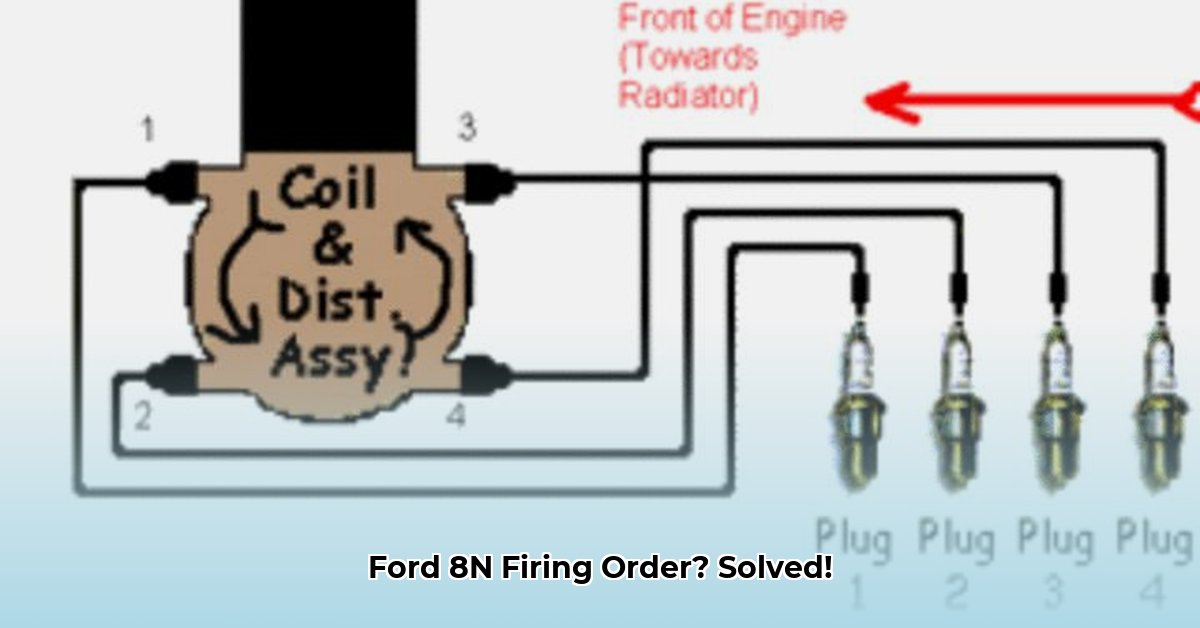

The Ford 8N tractor's ignition system, while seemingly simple, requires precision. Its 1-2-4-3 firing order dictates the sequence in which the cylinders ignite. Understanding this order, along with distributor rotation and Top Dead Center (TDC), is crucial for optimal engine performance. This guide provides a step-by-step approach to troubleshooting and maintaining your Ford 8N's ignition system. Are you ready to get your tractor running smoothly? For a visual aid, check out this helpful parts diagram.

Identifying Cylinders and Components

Before we proceed, let's identify your Ford 8N's engine components and cylinders. The cylinders (1-4) are typically numbered on the engine block. Key ignition system components include: the distributor (the brains of the operation), the rotor (a spinning component within the distributor), the distributor cap (protecting the rotor and connections), the points (electrical contacts triggering the spark), the condenser (a component aiding the points), the coil (stepping up the voltage to create a spark), the spark plugs (where the combustion magic occurs), and the spark plug wires (carrying the spark to the plugs). A labeled diagram will significantly aid identification. Did you know that a properly identified engine setup is 95% of successfully firing your Ford 8N?

Determining Distributor Rotation

A common source of confusion lies in the distributor's rotation: clockwise or counter-clockwise? This isn't standardized across all Ford 8N models. The best approach is direct observation. Carefully crank the engine (by hand or with the starter, ensuring safety precautions) and note the distributor's rotation. This directly impacts spark plug wire routing and the firing order. Misinterpreting this can lead to misfires, poor performance, or worse. What's your distributor's rotation?

Locating Top Dead Center (TDC)

Finding TDC (Top Dead Center) – the point where piston #1 reaches its highest point – is essential for accurate timing. If your engine block has timing marks, aligning them is straightforward. For engines lacking marks, use a method described in your owner's manual or a reputable repair guide. Precise TDC identification is critical; incorrect placement offsets the entire firing order, impacting engine performance.

Wiring the Spark Plug Wires: The 1-2-4-3 Sequence

With TDC established and distributor rotation confirmed, connect the spark plug wires according to the 1-2-4-3 firing order. This means: cylinder 1, then 2, then 4, and finally 3. A clearly labeled diagram is invaluable. Incorrect wiring is a common pitfall; double-check your connections. Do you have a visual guide to help ensure accurate wiring?

Troubleshooting Misfires: A Systematic Approach

Misfires (a cylinder failing to ignite) are often a sign of a problem with the ignition system. Follow this sequence:

- Spark Plugs: Inspect for wear, cracks, or fouling. Replace if necessary.

- Spark Plug Wires: Check for damage, cracks, or loose connections. Replace as needed.

- Distributor Components: Examine the cap, rotor, points, and condenser for wear or damage. Replace worn components.

- Ignition Coil: Test the coil’s output using a multimeter. If unsure, contact a qualified mechanic.

This structured approach increases your chances of quickly identifying and fixing the root cause. What's your first troubleshooting step?

6V vs. 12V Coil Upgrades: A Cautious Approach

Upgrading to a 12V coil improves performance but requires careful attention. Incorrect wiring can damage the ignition system. Consult a wiring diagram specifically for this upgrade. Adding a ballast resistor might be needed. This is not a beginner's task. It’s important to consult with a mechanic if you aren't completely confident in this modification. What are the necessary safety precautions for this upgrade?

Regular Maintenance: Preventative Care

Regular maintenance is crucial. Clean or replace points and condensers, inspect the cap and rotor, and regularly check spark plugs and wires. Proactive maintenance extends the life of your ignition system and avoids costly repairs in the future. What is the recommended maintenance schedule?

Conclusion: Ensuring Smooth Operation

Understanding the 1-2-4-3 firing order is key to a smoothly running Ford 8N. Following this guide and taking your time will ensure successful ignition. Remember, careful attention to detail prevents future issues and keeps your tractor running efficiently.